Supply Chain Management: Optimize Your Operations for Success

Understanding Supply Chain Management

Introduction:

Supply Chain Management (SCM) plays a critical role in ensuring the smooth flow of goods and services from raw materials to the end consumers. It encompasses the coordination, control, and optimization of various activities involved in the production, distribution, and delivery process. For individuals and businesses alike, understanding the core principles and best practices of SCM is vital to stay competitive in today’s global marketplace.

The Importance of Supply Chain Management

Bullet points:

– Enhances efficiency and reduces costs: By streamlining processes and optimizing inventory levels, SCM helps eliminate bottlenecks and minimize costs, ultimately resulting in higher profitability.

– Improves customer satisfaction: SCM ensures timely delivery, reduces order fulfillment errors, and enhances overall customer experience, leading to increased loyalty and repeat business.

– Enhances collaboration and visibility: Effective SCM enables better collaboration among suppliers, manufacturers, and retailers, fostering improved communication and real-time visibility into the supply chain.

– Mitigates risks: SCM enables businesses to identify potential risks and implement strategies to mitigate them. This includes managing disruptions, ensuring supply chain continuity, and developing contingency plans.

Historical Evolution of Supply Chain Management

Bullet points:

– Early roots in manufacturing: SCM can be traced back to the industrial revolution, where organizations began to focus on optimizing production and improving overall efficiency.

– Rise of materials management: In the mid-20th century, materials management emerged as a key aspect of SCM, emphasizing the procurement, storage, and control of raw materials.

– The advent of integrated logistics: In the 1960s and 1970s, the concept of integrated logistics gained prominence, emphasizing the need for a coordinated approach to transportation, warehousing, and inventory management.

– The emergence of global supply chains: With technological advancements and globalization, supply chains expanded beyond geographical boundaries, leading to the need for efficient coordination and collaboration across international markets.

– The era of digitalization: The 21st century brought significant advancements in technology, leading to the integration of digital systems, analytics, and automation into SCM, revolutionizing the way businesses manage their supply chains.

Structuring Your Supply Chain Management Approach

Bullet points:

1. Demand forecasting and planning:

– Accurately predict customer demand to avoid stockouts or excess inventory.

– Leverage forecasting models, market research, and historical data to optimize inventory levels.

2. Supplier relationship management:

– Develop strategic partnerships with suppliers to ensure consistent and reliable access to raw materials.

– Establish clear communication channels and align goals to foster mutual success.

3. Inventory management:

– Employ inventory optimization techniques to strike the right balance between customer demand and carrying costs.

– Use advanced technologies, such as RFID and barcode systems, to enhance inventory visibility and accuracy.

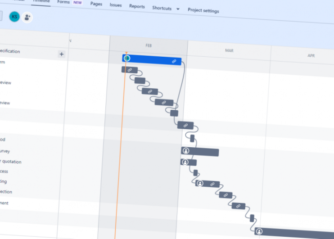

4. Logistics and transportation:

– Optimize transportation routes and modes to minimize costs and reduce delivery lead times.

– Leverage technology solutions, such as route optimization software, to streamline operations and improve efficiency.

5. Warehouse management:

– Implement efficient warehousing processes, layout designs, and automated systems to enhance productivity and reduce errors.

– Embrace lean principles to eliminate waste and improve overall operational efficiency.

6. Reverse logistics:

– Develop a robust returns management process to handle product returns, repairs, or recycling effectively.

– Analyze and address the root causes of returns to minimize their impact on the supply chain.

Conclusion:

Supply Chain Management serves as the backbone of successful businesses, ensuring seamless coordination, cost efficiency, and customer satisfaction. By understanding the historical evolution, core principles, and best practices in SCM, individuals and organizations can optimize their operations, gain a competitive edge, and thrive in today’s dynamic marketplace.